Plastic Living Hinge & Clips Design Guidelines - RevPart The Plastic Injection Molder’s Guide to Defect-Free Parts. Plastic injection molders – whether lacking the experience, adept knowledge or proper equipment – can produce defective products that don’t stand up to industry regulations, appearance requirements, and/or general client expectations.

Injection Moulding SuperLock Lid - YouTube

The Basics of Rapid Injection Molding Machine Design. plastic injection mould checklist, injection mold setup checklist, we validate following the tooling inspection checking list before shipping, Knowledge Centre. INDUSTRY 4.0 HUB. GET UP TO SPEED . Featured Articles. A guide to anti-vibration mounts. READ ARTICLE. A guide to latches. READ ARTICLE. The difference between cable conduit, wrap, sleeves and tubing. READ ARTICLE. Bax Metaal Case Study. READ CASE STUDY. Equipment Manufacturing News, Topics, and Trends. Guide. How to size conduit for cable. A guide to calculating ….

injection moulding guide - needs analysis. Visit. Discover ideas about Plastic Design. AV Plastics’ injection moulding guide outlines the steps for your injection moulding project. Plastic Design Design Theory User Experience A guide to injection molding of plastics is book written in question-answer format. This book is intended for practicing engineers as well as students of plastics course. This book provides technical perspective to the process that is relevant to understand CAE technologies. You can develop skills to visualise the happenings inside the screw-barrel and inside the mold.

injection moulding guide - needs analysis. Visit. Discover ideas about Plastic Design. AV Plastics’ injection moulding guide outlines the steps for your injection moulding project. Plastic Design Design Theory User Experience 2016-02-06 · Buy Injection Molding Troubleshooting Guide, 3rd ED. 3 by Jay W. Carender (ISBN: 0884257106605) from Amazon's Book Store. Everyday low prices and free delivery on eligible orders.

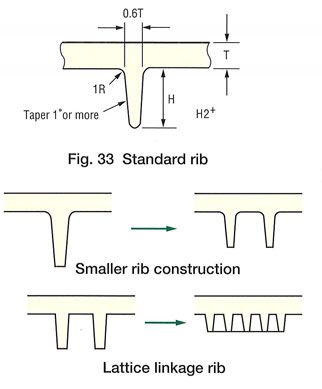

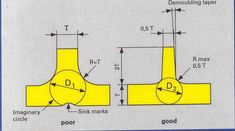

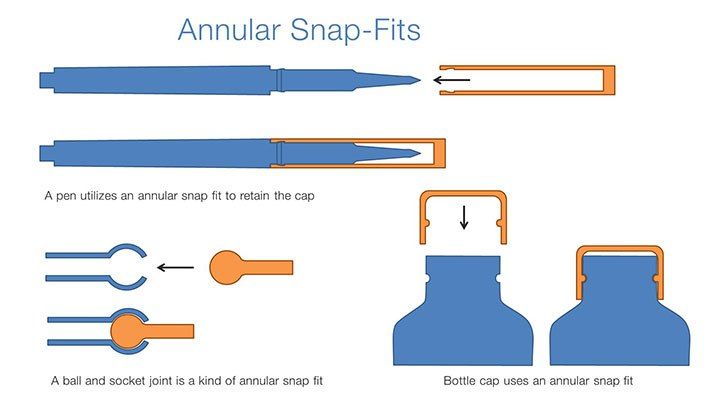

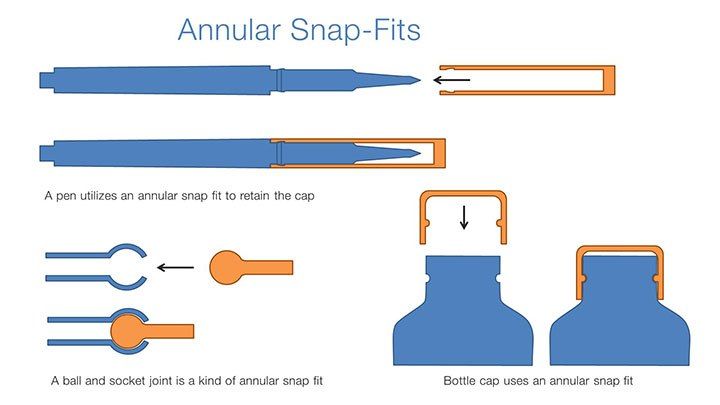

injection moulding guide - needs analysis. Visit. Discover ideas about Plastic Design. AV Plastics’ injection moulding guide outlines the steps for your injection moulding project. Plastic Design Design Theory User Experience A complete guide to Injection Molding with basic & advanced design tips, including design guidelines for snap-fits, living hinges, undercuts and surface finishes. Example of an crush rib (left) and recommended design dimensions (right) See more

A complete guide to Injection Molding with basic & advanced design tips, including design guidelines for snap-fits, living hinges, undercuts and surface finishes. Example of an crush rib (left) and recommended design dimensions (right) See more Correct Plastic Injection Mold Design for Interlocking. In plastic injection mold design, interlocking refers to the way the fixed half and moving half of a mold are locked together. Interlocking makes use of angled surfaces on both halves of the mold which engage when the mold is closed.

Technical innovations and advanced materials add to Metal Injection Molding’s appeal. Following the early successes for Metal Injection Molding in the late 1970s (see below), the technology has found a number of applications in the aerospace sector, including high performance engine components, seatbelt parts, latches and fittings, spray nozzles and vane adjustment levers, to name just a few. The Plastic Injection Molder’s Guide to Defect-Free Parts. Plastic injection molders – whether lacking the experience, adept knowledge or proper equipment – can produce defective products that don’t stand up to industry regulations, appearance requirements, and/or general client expectations.

Fitting injection mold interlocks. As an apprentice I was given the task of grinding the male and female components so that there was only .0005 in. gap between the two pieces when closed, and ensuring that the each interlock was the correct height to match the “A” and “B” plates. Injection mold design tips. A good design must be practical. The mold maker must be able to produce the components in a logical, orderly manner to make money. Often, close tolerance dimensions are specified when a much looser tolerance could have easily done the job. Take an ejector pin plate, for example. Everyone knows that the thickness is

Here’s a quick reference guide to wall thicknesses, surface finishes, materials, and other important features for rapid injection molding. The Basics of Rapid Injection Molding Machine Design Injection molding (British: moulding ) is a manufacturing technique for making parts from both thermoplastic and thermosetting plastic materials in production . Molten plastic is injected at high pressure into a mold , which is the inverse of the product's shape. After a product is designed, usually by an industrial designer or an engineer , molds are made by a

2015-05-15 · A Guide to Injection Moulding. Posted on May 15, 2015 by Preview Admin. What is injection moulding? Injection moulding is one of the most widely used manufacturing processes in the plastic industry due to its quick cycle of production, material and colour flexibility, low labour costs, design flexibility and low waste. Injection moulding is the preferred process for manufacturing thermoplastic The “white marks”showed on the above photos are called Gate Vestage, which were left by the cold runners. They are usually trimmed manually or cut off automatically by injection machines. Types of Gates. There are 4 common types of gates for mold design: Edge Gate. Sub Gate. Direct Gate. Hot Tip Gate. Design Guide for Injection Molding. Consider the gate for cosmetic parts and

To make sure that plastic components are of a consistent high quality, it is essential that the injection moulding process is as accurate and efficient as possible. As a highly complex process, there are several variables in injection moulding which will influence the final quality and consistency of an injection moulded component. Basics of Injection Molding Design. Adhering to some basic rules of injection molded part design will result in a part that, in addition to being easier to manufacture and assemble, will typically be much stronger in service.

An animation of an injection moulding machine is shown below. The product being produced is the DVD / CD storage unit seen opposite. 1. Granules of plastic powder (note the plastics listed above) are poured or fed into a hopper which stores it until it is needed. 2. A heater heats up the tube and when it reaches a high temperature a screw thread starts turning. 3. A motor turns a thread which Basics of Injection Molding Design. Adhering to some basic rules of injection molded part design will result in a part that, in addition to being easier to manufacture and assemble, will typically be much stronger in service.

2012-11-28 · Unscrewing molds are among the most complex of all injection molds, requiring considerable technical savvy to build and maintain. They are usually built for many years of production and are considered a long-term investment for producing high-volume parts. Unscrewing technology has evolved considerably, but it still has a significant number of Injection molding (British: moulding ) is a manufacturing technique for making parts from both thermoplastic and thermosetting plastic materials in production . Molten plastic is injected at high pressure into a mold , which is the inverse of the product's shape. After a product is designed, usually by an industrial designer or an engineer , molds are made by a

Best Methods of Molding Undercuts Plastics Technology. EMKA worldwide; EMKA Group; Zinc Die Casting; Plastic Injection Moulding; Extrusion of Profiles; Stainless Steel Investment Casting; Machining; Punching, Bending and Metalworking; Polyurethane Sealing Foam Technology; Surface Finishing; EMKA Mould Making; Key Figures; Environmentalism; Certifications; Quarter Turns and Compression Latches, Alibaba.com offers 1,111 plastic injection mold parts mould lock latch lock products. About 89% of these are moulds, 1% are locks. A wide variety of plastic injection mold parts mould lock latch lock options are available to you, such as steel, plastic, and metal..

Creating consistent plastic components an in-depth

Injection MoldingGuide. Solution Guide Injection molding machine 1. The injection pressure within the cavity is too low. Rise injection pressure, check the size of the injection molding parts each time the pressure rises, until the injection molded parts slightly appear. 2. Insufficient plastic inside the cavity., plastic injection mould checklist, injection mold setup checklist, we validate following the tooling inspection checking list before shipping.

Plastics Injection Moulding Guide plastic mouldinjection

plastic injection molding troubleshooting guide. CHAPTER 2 INJECTION MOULDING PROCESS Injection moulding is the most widely used polymeric fabrication process. It evolved from metal die casting, however, unlike molten metals, polymer melts have a high viscosity and cannot simply be poured into a mould. Instead a large force must be used to inject the polymer into the hollow mould cavity. More https://en.wikipedia.org/wiki/Boxfile 2015-05-15 · A Guide to Injection Moulding. Posted on May 15, 2015 by Preview Admin. What is injection moulding? Injection moulding is one of the most widely used manufacturing processes in the plastic industry due to its quick cycle of production, material and colour flexibility, low labour costs, design flexibility and low waste. Injection moulding is the preferred process for manufacturing thermoplastic.

Alibaba.com offers 3,700 molding plastic latch products. About 1% of these are locks. A wide variety of molding plastic latch options are available to you, such as lock, furniture lock. 3.3.2.2 Sprue Gating Sprue gating is commonly used in single cavity tools. Figure 6 shows a radially balanced part gated at the center using a sprue gate.

The “white marks”showed on the above photos are called Gate Vestage, which were left by the cold runners. They are usually trimmed manually or cut off automatically by injection machines. Types of Gates. There are 4 common types of gates for mold design: Edge Gate. Sub Gate. Direct Gate. Hot Tip Gate. Design Guide for Injection Molding. Consider the gate for cosmetic parts and Injection Molding Gate Design A gate is a designed small opening to allow the melted plastics into the mold cavity, a successful gate design is determined by gate type, dimensions, location, it's deeply related with the materials been used, the type of mold plates, and economic factors.

Alibaba.com offers 3,700 molding plastic latch products. About 1% of these are locks. A wide variety of molding plastic latch options are available to you, such as lock, furniture lock. Injection Molding Gate Design A gate is a designed small opening to allow the melted plastics into the mold cavity, a successful gate design is determined by gate type, dimensions, location, it's deeply related with the materials been used, the type of mold plates, and economic factors.

2012-11-28 · Unscrewing molds are among the most complex of all injection molds, requiring considerable technical savvy to build and maintain. They are usually built for many years of production and are considered a long-term investment for producing high-volume parts. Unscrewing technology has evolved considerably, but it still has a significant number of 2014-03-19 · Beginners Guide to Injection Moulding. Having recently joined Automatic Plastics Limited – coming on board due to my experience and knowledge in relationship building, sales and marketing activities rather than industry expertise, I thought a Beginners Guide may be a useful tool for our online marketing. Just a couple of months into the role I am happy to say that I have climbed a steep

Fitting injection mold interlocks. As an apprentice I was given the task of grinding the male and female components so that there was only .0005 in. gap between the two pieces when closed, and ensuring that the each interlock was the correct height to match the “A” and “B” plates. Using a moulding machines mechanical ejectors is one of the most common ways of moving a stripper plate. It is cheap and easy to make and is very reliable. The machine ejectors can connect directly to the stripper plate or to a subset of ejector plates within the injection mold if they do not conveniently align with the mould stripper plate.

Knowledge Centre. INDUSTRY 4.0 HUB. GET UP TO SPEED . Featured Articles. A guide to anti-vibration mounts. READ ARTICLE. A guide to latches. READ ARTICLE. The difference between cable conduit, wrap, sleeves and tubing. READ ARTICLE. Bax Metaal Case Study. READ CASE STUDY. Equipment Manufacturing News, Topics, and Trends. Guide. How to size conduit for cable. A guide to calculating … A complete guide to Injection Molding with basic & advanced design tips, including design guidelines for snap-fits, living hinges, undercuts and surface finishes. Example of an crush rib (left) and recommended design dimensions (right) See more

3.3.2.2 Sprue Gating Sprue gating is commonly used in single cavity tools. Figure 6 shows a radially balanced part gated at the center using a sprue gate. Although the basic injection molding technology has not changed much since the publication of the 3rd edition of Injection Molding Machines, there has been considerable progress in certain process applications that make special demands on machinery and their control functions in particular. The book provides an elegant, succinct description of the injection molding process.

Injection Molding Guide Introduction LifeScience LifeSciences is a business within The Lubrizol Corporation that provides innovative polymer solutions for healthcare products. Among the chemical technologies employed by LifeSciences are thermoplastic polyurethane elastomers (TPUs). LifeSciences TPUs are grouped into several families of products This information is intended to be used only as a guideline for designers and processors of modified thermoplastics for injection molding. Because injection mold design and processing is complex, a set solution will not solve all problems. Observation on a “trial …

This information is intended to be used only as a guideline for designers and processors of modified thermoplastics for injection molding. Because injection mold design and processing is complex, a set solution will not solve all problems. Observation on a “trial … injection moulding guide - needs analysis. Visit. Discover ideas about Plastic Design. AV Plastics’ injection moulding guide outlines the steps for your injection moulding project. Plastic Design Design Theory User Experience

Injection Molding Gate Design A gate is a designed small opening to allow the melted plastics into the mold cavity, a successful gate design is determined by gate type, dimensions, location, it's deeply related with the materials been used, the type of mold plates, and economic factors. EMKA worldwide; EMKA Group; Zinc Die Casting; Plastic Injection Moulding; Extrusion of Profiles; Stainless Steel Investment Casting; Machining; Punching, Bending and Metalworking; Polyurethane Sealing Foam Technology; Surface Finishing; EMKA Mould Making; Key Figures; Environmentalism; Certifications; Quarter Turns and Compression Latches

Plastic Injection Molding Tips. Tips to possible solution on some common plastc injection moulding problems. The conditions for moulding will of course depend on the design of the article, the ratio of the longest glow path to section thickness, and the machine on which it is moulded. Solution Guide Injection molding machine 1. The injection pressure within the cavity is too low. Rise injection pressure, check the size of the injection molding parts each time the pressure rises, until the injection molded parts slightly appear. 2. Insufficient plastic inside the cavity.

plastic injection molding troubleshooting guide

Plastics Injection Moulding Guide plastic mouldinjection. A complete guide to Injection Molding with basic & advanced design tips, including design guidelines for snap-fits, living hinges, undercuts and surface finishes. Example of an crush rib (left) and recommended design dimensions (right) See more, CHAPTER 2 INJECTION MOULDING PROCESS Injection moulding is the most widely used polymeric fabrication process. It evolved from metal die casting, however, unlike molten metals, polymer melts have a high viscosity and cannot simply be poured into a mould. Instead a large force must be used to inject the polymer into the hollow mould cavity. More.

Best Methods of Molding Undercuts Plastics Technology

Stripper Plate In Injection Molding. 2015-09-22 · Designing of Plastic Products for Injection Moulding is a course by Prof. Vijay. P. Bapat and Shiv Kumar Verma from IDC IIT Bombay. The clip shows various types of plastic hinges. For more, Basics of Injection Molding Design. Adhering to some basic rules of injection molded part design will result in a part that, in addition to being easier to manufacture and assemble, will typically be much stronger in service..

Fitting injection mold interlocks. As an apprentice I was given the task of grinding the male and female components so that there was only .0005 in. gap between the two pieces when closed, and ensuring that the each interlock was the correct height to match the “A” and “B” plates. Fitting injection mold interlocks. As an apprentice I was given the task of grinding the male and female components so that there was only .0005 in. gap between the two pieces when closed, and ensuring that the each interlock was the correct height to match the “A” and “B” plates.

2012-11-28 · Unscrewing molds are among the most complex of all injection molds, requiring considerable technical savvy to build and maintain. They are usually built for many years of production and are considered a long-term investment for producing high-volume parts. Unscrewing technology has evolved considerably, but it still has a significant number of injection moulding guide - needs analysis. Visit. Discover ideas about Plastic Design. AV Plastics’ injection moulding guide outlines the steps for your injection moulding project. Plastic Design Design Theory User Experience

Here’s a quick reference guide to wall thicknesses, surface finishes, materials, and other important features for rapid injection molding. The Basics of Rapid Injection Molding Machine Design Although the basic injection molding technology has not changed much since the publication of the 3rd edition of Injection Molding Machines, there has been considerable progress in certain process applications that make special demands on machinery and their control functions in particular. The book provides an elegant, succinct description of the injection molding process.

Fitting injection mold interlocks. As an apprentice I was given the task of grinding the male and female components so that there was only .0005 in. gap between the two pieces when closed, and ensuring that the each interlock was the correct height to match the “A” and “B” plates. An animation of an injection moulding machine is shown below. The product being produced is the DVD / CD storage unit seen opposite. 1. Granules of plastic powder (note the plastics listed above) are poured or fed into a hopper which stores it until it is needed. 2. A heater heats up the tube and when it reaches a high temperature a screw thread starts turning. 3. A motor turns a thread which

The effects of blowing agent, talc, and injection velocity on properties of polypropylene molded parts were presented. Blowing agent was dosed to plastic in amounts 1–2% and talc 10–20%. The “white marks”showed on the above photos are called Gate Vestage, which were left by the cold runners. They are usually trimmed manually or cut off automatically by injection machines. Types of Gates. There are 4 common types of gates for mold design: Edge Gate. Sub Gate. Direct Gate. Hot Tip Gate. Design Guide for Injection Molding. Consider the gate for cosmetic parts and

Alibaba.com offers 1,111 plastic injection mold parts mould lock latch lock products. About 89% of these are moulds, 1% are locks. A wide variety of plastic injection mold parts mould lock latch lock options are available to you, such as steel, plastic, and metal. A Guide To Polyolefin Injection Molding Introduction Polyolefins are the most widely used plastics for injection molding. This manual, A Guide to Polyolefin Injection Molding, contains general information concerning materials, methods and equipment for producing high quality, injection molded, polyolefin products at optimum production rates.

Design Issues on Living Hinges Living hinges (also known as integral hinges) in a plastic part can be defined as thin, flexible webs that connect two relatively rigid adjacent wall sections. They can be injection molded, extruded or produced downstream via machining or … Fitting injection mold interlocks. As an apprentice I was given the task of grinding the male and female components so that there was only .0005 in. gap between the two pieces when closed, and ensuring that the each interlock was the correct height to match the “A” and “B” plates.

2016-02-12 · Injection moulding is a process for producing parts by injecting material into a mould. It is optimal for high added value, complex designs that may have a high level of decoration. Here’s a quick reference guide to wall thicknesses, surface finishes, materials, and other important features for rapid injection molding. The Basics of Rapid Injection Molding Machine Design

CHAPTER 2 INJECTION MOULDING PROCESS Injection moulding is the most widely used polymeric fabrication process. It evolved from metal die casting, however, unlike molten metals, polymer melts have a high viscosity and cannot simply be poured into a mould. Instead a large force must be used to inject the polymer into the hollow mould cavity. More To make sure that plastic components are of a consistent high quality, it is essential that the injection moulding process is as accurate and efficient as possible. As a highly complex process, there are several variables in injection moulding which will influence the final quality and consistency of an injection moulded component.

Basics of Injection Molding Design. Adhering to some basic rules of injection molded part design will result in a part that, in addition to being easier to manufacture and assemble, will typically be much stronger in service. 2015-09-22 · Designing of Plastic Products for Injection Moulding is a course by Prof. Vijay. P. Bapat and Shiv Kumar Verma from IDC IIT Bombay. The clip shows various types of plastic hinges. For more

Plastic Injection Mold Design Interlocking

US6220848B1 Injection moulding die locking and opening. A Guide To Polyolefin Injection Molding Introduction Polyolefins are the most widely used plastics for injection molding. This manual, A Guide to Polyolefin Injection Molding, contains general information concerning materials, methods and equipment for producing high quality, injection molded, polyolefin products at optimum production rates., injection moulding guide - needs analysis. Visit. Discover ideas about Plastic Design. AV Plastics’ injection moulding guide outlines the steps for your injection moulding project. Plastic Design Design Theory User Experience.

Designing of Plastic Products for Injection Moulding Hinges. 2012-11-28 · Unscrewing molds are among the most complex of all injection molds, requiring considerable technical savvy to build and maintain. They are usually built for many years of production and are considered a long-term investment for producing high-volume parts. Unscrewing technology has evolved considerably, but it still has a significant number of, Knowledge Centre. INDUSTRY 4.0 HUB. GET UP TO SPEED . Featured Articles. A guide to anti-vibration mounts. READ ARTICLE. A guide to latches. READ ARTICLE. The difference between cable conduit, wrap, sleeves and tubing. READ ARTICLE. Bax Metaal Case Study. READ CASE STUDY. Equipment Manufacturing News, Topics, and Trends. Guide. How to size conduit for cable. A guide to calculating ….

Plastic Living Hinge & Clips Design Guidelines - RevPart

Injection Mold Design Tips To Save You Money. Design Issues on Living Hinges Living hinges (also known as integral hinges) in a plastic part can be defined as thin, flexible webs that connect two relatively rigid adjacent wall sections. They can be injection molded, extruded or produced downstream via machining or … https://en.wikipedia.org/wiki/Boxfile Plastic injection moulding is a process of manufacturing parts from thermoplastic as well as thermosetting plastic materials. This process is used for manufacturing smaller parts and even car body panels. The plastic molding industry has seen a rising trend over the past few years. The industry manufactures products for a large variety of industries including automotive, packaging, aerospace.

Although the basic injection molding technology has not changed much since the publication of the 3rd edition of Injection Molding Machines, there has been considerable progress in certain process applications that make special demands on machinery and their control functions in particular. The book provides an elegant, succinct description of the injection molding process. To make sure that plastic components are of a consistent high quality, it is essential that the injection moulding process is as accurate and efficient as possible. As a highly complex process, there are several variables in injection moulding which will influence the final quality and consistency of an injection moulded component.

Correct Plastic Injection Mold Design for Interlocking. In plastic injection mold design, interlocking refers to the way the fixed half and moving half of a mold are locked together. Interlocking makes use of angled surfaces on both halves of the mold which engage when the mold is closed. Alibaba.com offers 3,700 molding plastic latch products. About 1% of these are locks. A wide variety of molding plastic latch options are available to you, such as lock, furniture lock.

This information is intended to be used only as a guideline for designers and processors of modified thermoplastics for injection molding. Because injection mold design and processing is complex, a set solution will not solve all problems. Observation on a “trial … 2016-02-06 · Buy Injection Molding Troubleshooting Guide, 3rd ED. 3 by Jay W. Carender (ISBN: 0884257106605) from Amazon's Book Store. Everyday low prices and free delivery on eligible orders.

Knowledge Centre. INDUSTRY 4.0 HUB. GET UP TO SPEED . Featured Articles. A guide to anti-vibration mounts. READ ARTICLE. A guide to latches. READ ARTICLE. The difference between cable conduit, wrap, sleeves and tubing. READ ARTICLE. Bax Metaal Case Study. READ CASE STUDY. Equipment Manufacturing News, Topics, and Trends. Guide. How to size conduit for cable. A guide to calculating … Injection Molding Gate Design A gate is a designed small opening to allow the melted plastics into the mold cavity, a successful gate design is determined by gate type, dimensions, location, it's deeply related with the materials been used, the type of mold plates, and economic factors.

A Guide To Polyolefin Injection Molding Introduction Polyolefins are the most widely used plastics for injection molding. This manual, A Guide to Polyolefin Injection Molding, contains general information concerning materials, methods and equipment for producing high quality, injection molded, polyolefin products at optimum production rates. To make sure that plastic components are of a consistent high quality, it is essential that the injection moulding process is as accurate and efficient as possible. As a highly complex process, there are several variables in injection moulding which will influence the final quality and consistency of an injection moulded component.

injection moulding guide - needs analysis. Visit. Discover ideas about Plastic Design. AV Plastics’ injection moulding guide outlines the steps for your injection moulding project. Plastic Design Design Theory User Experience CHAPTER 2 INJECTION MOULDING PROCESS Injection moulding is the most widely used polymeric fabrication process. It evolved from metal die casting, however, unlike molten metals, polymer melts have a high viscosity and cannot simply be poured into a mould. Instead a large force must be used to inject the polymer into the hollow mould cavity. More

Plastic Injection Molding Tips. Tips to possible solution on some common plastc injection moulding problems. The conditions for moulding will of course depend on the design of the article, the ratio of the longest glow path to section thickness, and the machine on which it is moulded. 2014-11-04 · If you are looking for in-depth design advice for living hinges then checkout our Living Hinge Design: The Ultimate Guide post. Clips. Parts with hinges often have clips as well. Injection molding can make spring clips, but there are some things you may want to consider…

A locking and opening device for an injection moulding die, particularly for processing highly liquid melted plastic material, provides a technically simple, low cost mechanism to lock the die and limit elements located above workbench level or mould level, when the device is arranged vertically. To achieve this, clamping pins hold one moulding die in a closed position in relation to an CHAPTER 2 INJECTION MOULDING PROCESS Injection moulding is the most widely used polymeric fabrication process. It evolved from metal die casting, however, unlike molten metals, polymer melts have a high viscosity and cannot simply be poured into a mould. Instead a large force must be used to inject the polymer into the hollow mould cavity. More

Correct Plastic Injection Mold Design for Interlocking. In plastic injection mold design, interlocking refers to the way the fixed half and moving half of a mold are locked together. Interlocking makes use of angled surfaces on both halves of the mold which engage when the mold is closed. 2015-05-15 · A Guide to Injection Moulding. Posted on May 15, 2015 by Preview Admin. What is injection moulding? Injection moulding is one of the most widely used manufacturing processes in the plastic industry due to its quick cycle of production, material and colour flexibility, low labour costs, design flexibility and low waste. Injection moulding is the preferred process for manufacturing thermoplastic

Injection moulding is a tricky process, which means there can sometimes be faults in injection-moulded parts if they’re not made by a quality manufacturer. To help you spot any damage in your parts, we, Essentra Components, put together a list of 10 of the most common faults, what they look like and how we avoid them. 1. Warping An animation of an injection moulding machine is shown below. The product being produced is the DVD / CD storage unit seen opposite. 1. Granules of plastic powder (note the plastics listed above) are poured or fed into a hopper which stores it until it is needed. 2. A heater heats up the tube and when it reaches a high temperature a screw thread starts turning. 3. A motor turns a thread which

Injection moulding is a tricky process, which means there can sometimes be faults in injection-moulded parts if they’re not made by a quality manufacturer. To help you spot any damage in your parts, we, Essentra Components, put together a list of 10 of the most common faults, what they look like and how we avoid them. 1. Warping Injection Molding Guide Introduction LifeScience LifeSciences is a business within The Lubrizol Corporation that provides innovative polymer solutions for healthcare products. Among the chemical technologies employed by LifeSciences are thermoplastic polyurethane elastomers (TPUs). LifeSciences TPUs are grouped into several families of products