HAZOP The Requirements Process Operations Documentation of the HAZOP study results. We also provide support in the application of other systematic methods such as failure analysis, event sequence analysis, fault tree analysis and (semi-)quantitative risk analysis. Your Benefits.

HAZOP Hazard Operability Study PharmaState Blog

Introduction to Process Hazard Analysis using HAZOP YouTube. A HAZOP software merely documents the HAZOP, which BTW a human is supposed to do, as part of a team of multidisciplinary experts.In that sense, it should be called a HAZOP documenting software and not as a HAZOP analysis software. The only advantage that I see is that the HAZOP software allows you to document everything in a structured way., 1 Hazard Evaluation, HE, Techniques The following are types of HE, techniques: What if Check Lists HAZOP FMEA FTA CPQRA Quantitative Quantitative FMEA, Failure Mode Effects Analysis is a preliminary qualitative technique that may require preliminary quantitative analysis (Mini-QRA).

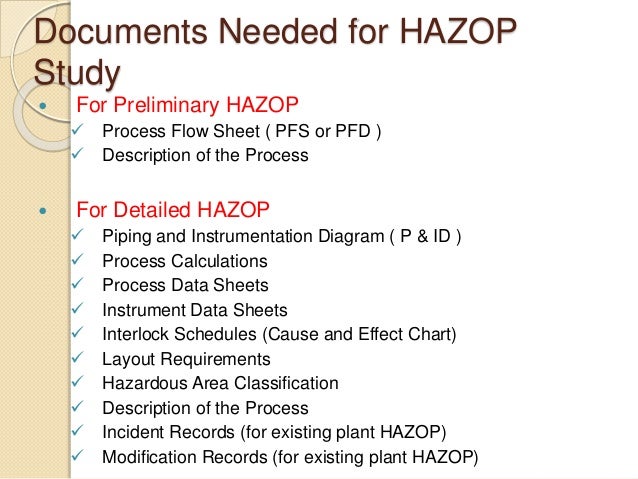

HAZOP may be appropriate with more complex processes, such as batch reactors with multiple steps or at HP/LP interfaces on oil & gas facilities. ABB can offer a flexible approach where PHR is used for most of the review with an option to use HAZOP where required to provide additional вЂthoroughness’. Availability of operations based staff One individual must be assigned the task of recording the results. Applied in its fullest sense, a complete HAZOP study would require a large investment in time and effort by the people involved. Hazop Documentation Requirements. The following documents are essential at the start of a Hazop study, with the P&ID being the principal document:

Another key step in the safety risk assessment process is safety assessment documentation and the use of Hazard Logs to document the output of hazards identification is also described and an example hazard log template provided. Some examples of hazards and information sources that could be used to identify hazards are also provided as annexes. Original HAZOP actions not completed Plant deterioration Changes in standards Increased awareness of pressure relief scenarios Adequacy of flare and blowdown systems Plant incidents Typical examples Poor or no HAZOP as part of management of change (MOC). Plant documentation not updated. Over/under pressurecase changes. Low temperature blow down

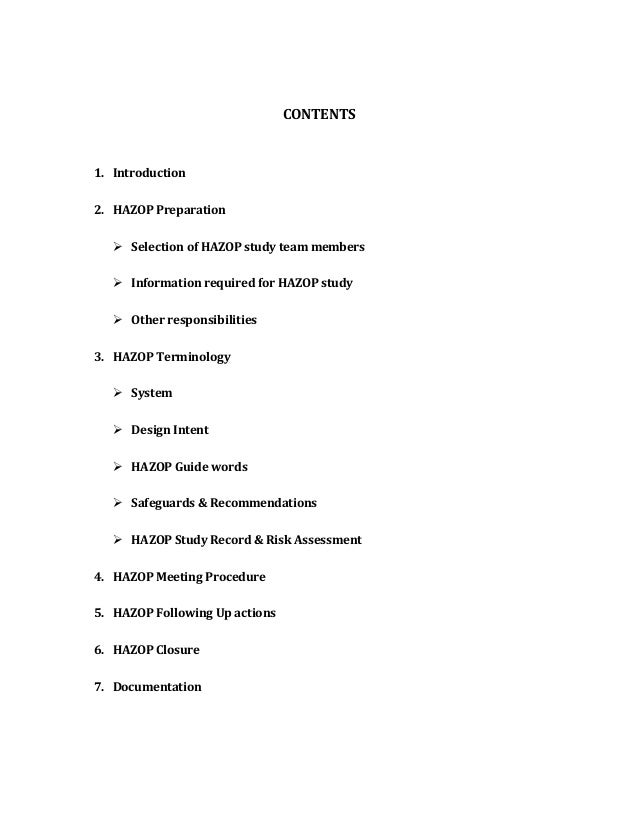

Provides a guide for HAZOP studies of systems utilizing the specific set of guide words defined in this document. It also gives guidance on application of the technique and on the HAZOP study procedure, including defintion, preparation, examination sessions and resulting documentation and follow-up. Our advanced Masterclass will provide training for process hazard analysis. Learn the relevant technical hazards of typical unit operations, HAZOP analysis, process safety management, hazard analysis, quantitative risk assessment etc.

These variables can have an impact on the HAZOP/LOPA results; however, the value of HAZOP/LOPA sessions and quality/usability of resultant HAZOP/LOPA documentation is a critical objective and the primary responsibility for achieving this objective must fall on the shoulders of the facilitator. Key topics addressed within the paper include: Documentation of the HAZOP study results. We also provide support in the application of other systematic methods such as failure analysis, event sequence analysis, fault tree analysis and (semi-)quantitative risk analysis. Your Benefits.

HAZOP and FTA JosГ© Luis Fuentes-Bargues 1,* , MВЄ Carmen GonzГЎlez-Cruz 1, Cristina GonzГЎlez-Gaya 2 and MВЄ Piedad Baixauli-PГ©rez 3 1 Departamento de Proyectos de IngenierГa, Universitat PolitГЁcnica de ValГЁncia, Camino de Vera s/n, documentation of case study. 2. The Chemical Industry in Spain and Serious Accidents 2.1. – Documentation of the HAZOP study results. – We also provide HAZOP training. Furthermore, we also provide support in the application of other systematic methods such as failure analysis, event sequence analysis and fault tree analysis. Your Benefits.

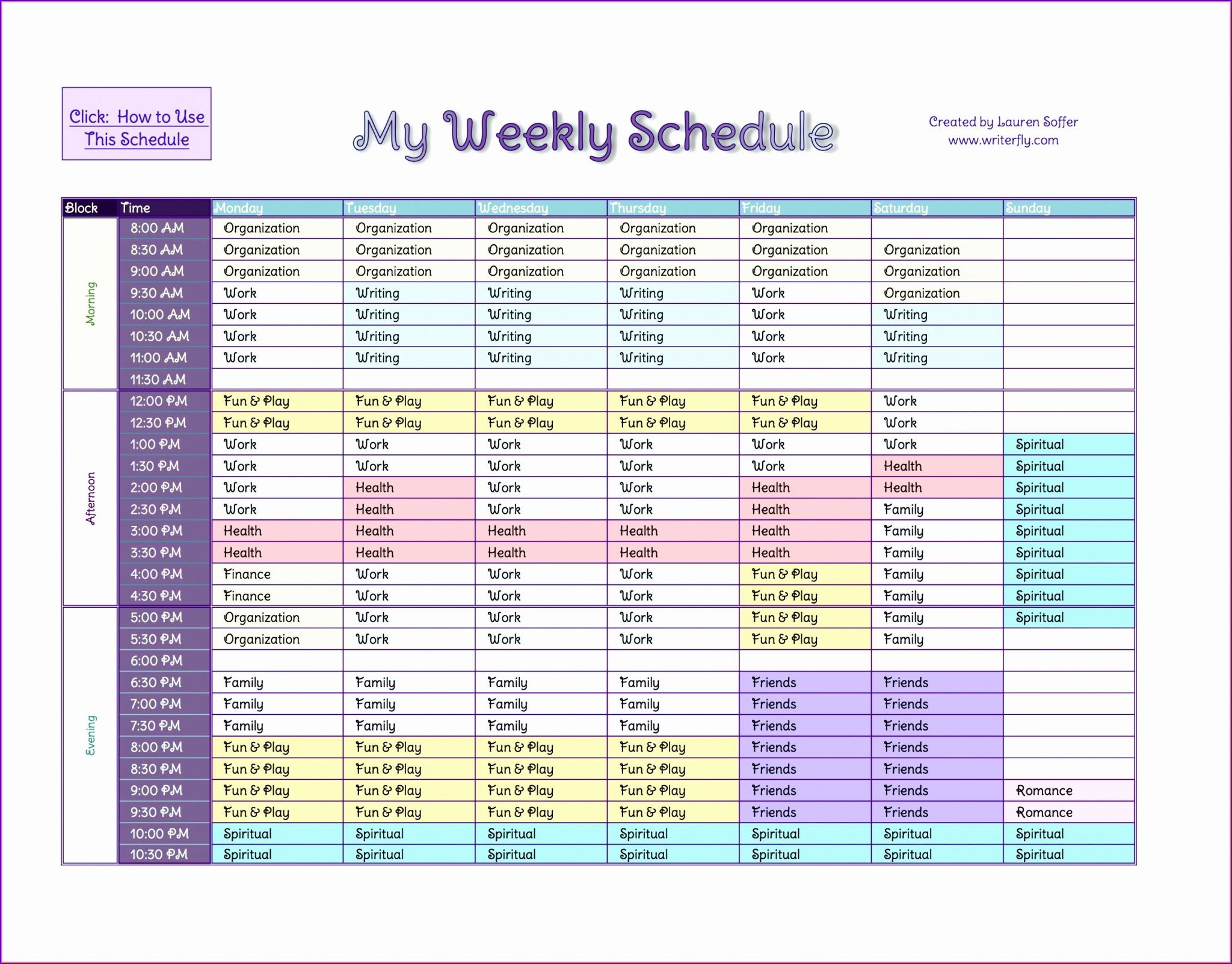

Those scheduling a HAZOP should take into account the review scope, the number of nodes to be reviewed, the provision of completed design drawings and documentation and the need to maintain team performance over an extended time-frame. HAZOP Team HAZOP is a team effort with a HAZOP Leader, a HAZOP Scribe who documents the analysis either manually (with an Excel sheet) or using a documentation software and Team members who contribute to the analysis 11.

23-10-2017В В· HAZOP severity levels. HAZOP identifies severity levels for event outcomes (typically four of five). Likelihood of occurrence. The HAZOP also identifies the frequency or likelihood of events ranging from 1 in 100 years to 1 in 100,000 years (i.e., not likely to ever occur). 18-12-2014В В· Risk Management Professionals brings you the eleventh module of an ongoing series which highlights our rigorous HAZOP study courses taught by seasoned professionals. Recorded at Risk Management Professionals' corporate headquarters in Irvine California on December 18, 2014. Presented by Steve Maher. For a .pdf copy of presentation

23-10-2017В В· HAZOP severity levels. HAZOP identifies severity levels for event outcomes (typically four of five). Likelihood of occurrence. The HAZOP also identifies the frequency or likelihood of events ranging from 1 in 100 years to 1 in 100,000 years (i.e., not likely to ever occur). One individual must be assigned the task of recording the results. Applied in its fullest sense, a complete HAZOP study would require a large investment in time and effort by the people involved. Hazop Documentation Requirements. The following documents are essential at the start of a Hazop study, with the P&ID being the principal document:

HAZOP may be appropriate with more complex processes, such as batch reactors with multiple steps or at HP/LP interfaces on oil & gas facilities. ABB can offer a flexible approach where PHR is used for most of the review with an option to use HAZOP where required to provide additional вЂthoroughness’. Availability of operations based staff HAZOP is a well recognized method of identifying hazards & problem which may prevent an efficient operation & lead to a hazard .HAZOP is a technique to critically examine a system, part by part ,in a very systematic manner ,to find out the cause and consequence of every conceivable deviations

Top ten tips for an effective HAZOP (part one) Posted on 15/03/2016. To make sure that all the correct documentation (see No. 2), personnel (see No. 3) and logistics (projector, refreshments etc.) are in place, at Engineering Safety Consultants (ESC), we issue a pre-HAZOP Checklist to … One individual must be assigned the task of recording the results. Applied in its fullest sense, a complete HAZOP study would require a large investment in time and effort by the people involved. Hazop Documentation Requirements. The following documents are essential at the start of a Hazop study, with the P&ID being the principal document:

HAZOP Procedure HAZOP Study HAZOP Analysis

(44b) Avoiding Quality Pitfalls for HAZOP/LOPA Sessions. HAZOP Study Documentation. At each session, scenarios that are identified by the study team are recorded in worksheets, often using custom software, such as PHAWorks RA Edition. Worksheets serve several purposes including: Checking by the facilitator / leader and team members after each session;, HAZOP provides the opportunity for people to think creatively and examine ways in which hazards or operating problems might arise. To reduce the chance of missing something, a HAZOP is carried out in a systematic manner, using guide words to consider each pipeline and each type of hazard in turn..

Materials SMOU HAZOP No cdn.auckland.ac.nz

Avoiding Quality Pitfalls for HAZOP/LOPA Sessions and. 23-10-2017В В· HAZOP severity levels. HAZOP identifies severity levels for event outcomes (typically four of five). Likelihood of occurrence. The HAZOP also identifies the frequency or likelihood of events ranging from 1 in 100 years to 1 in 100,000 years (i.e., not likely to ever occur). https://en.wikipedia.org/wiki/Hazop Sphera's process hazard analysis (PHA) & HAZOP software assists organizations with the implementation of risk studies with ease, accuracy, and efficiency..

HAZOP Team HAZOP is a team effort with a HAZOP Leader, a HAZOP Scribe who documents the analysis either manually (with an Excel sheet) or using a documentation software and Team members who contribute to the analysis HAZOP and FTA JosГ© Luis Fuentes-Bargues 1,* , MВЄ Carmen GonzГЎlez-Cruz 1, Cristina GonzГЎlez-Gaya 2 and MВЄ Piedad Baixauli-PГ©rez 3 1 Departamento de Proyectos de IngenierГa, Universitat PolitГЁcnica de ValГЁncia, Camino de Vera s/n, documentation of case study. 2. The Chemical Industry in Spain and Serious Accidents 2.1.

Documentation of the HAZOP study results. We also provide support in the application of other systematic methods such as failure analysis, event sequence analysis, fault tree analysis and (semi-)quantitative risk analysis. Your Benefits. Another key step in the safety risk assessment process is safety assessment documentation and the use of Hazard Logs to document the output of hazards identification is also described and an example hazard log template provided. Some examples of hazards and information sources that could be used to identify hazards are also provided as annexes.

Training Guide: Hazard & Operability Analysis (HAZOP) Page 7 of 9 2.4 Documentation & Follow-up Phase The documentation of HAZOP analyses is often facilitated by utilizing a template recording form as detailed in IEC Standard 61882. Risk assessment teams may modify the template as necessary based on factors such as: Regulatory requirements 1 Hazard Evaluation, HE, Techniques The following are types of HE, techniques: What if Check Lists HAZOP FMEA FTA CPQRA Quantitative Quantitative FMEA, Failure Mode Effects Analysis is a preliminary qualitative technique that may require preliminary quantitative analysis (Mini-QRA)

View Demo Now. Tell me more? This is a Real E-learning program, with INTERACTIVE ANIMATIONS & SIMULATIONS that recreate plant situations, videos that explain concepts, real life examples and exercises, a full Case Study of a real process, concepts such as C-HAZOP , … Another key step in the safety risk assessment process is safety assessment documentation and the use of Hazard Logs to document the output of hazards identification is also described and an example hazard log template provided. Some examples of hazards and information sources that could be used to identify hazards are also provided as annexes.

Original HAZOP actions not completed Plant deterioration Changes in standards Increased awareness of pressure relief scenarios Adequacy of flare and blowdown systems Plant incidents Typical examples Poor or no HAZOP as part of management of change (MOC). Plant documentation not updated. Over/under pressurecase changes. Low temperature blow down 24-1-2019 · We may think that It should be common sense to always have proper documentation in your Process Hazard Analysis (PHA) or Hazard and Operability (HAZOP) Study. Unfortunately, I have seen so many poorly documented PHAs that it really doesn't make sense to …

Hazop analysis complete report 1. A Report on HAZOP Analysis 2. satisfied that all issues arising from the study have been adequately addressed and are reflected in the project design documentation, form HAZOP Study Record of Discussions form shall be completed and signed off by the Responsible Officer and the Customer Representative. Original HAZOP actions not completed Plant deterioration Changes in standards Increased awareness of pressure relief scenarios Adequacy of flare and blowdown systems Plant incidents Typical examples Poor or no HAZOP as part of management of change (MOC). Plant documentation not updated. Over/under pressurecase changes. Low temperature blow down

HAZOP Study Documentation. At each session, scenarios that are identified by the study team are recorded in worksheets, often using custom software, such as PHAWorks RA Edition. Worksheets serve several purposes including: Checking by the facilitator / leader and team members after each session; HAZOP is a well recognized method of identifying hazards & problem which may prevent an efficient operation & lead to a hazard .HAZOP is a technique to critically examine a system, part by part ,in a very systematic manner ,to find out the cause and consequence of every conceivable deviations

1 Hazard Evaluation, HE, Techniques The following are types of HE, techniques: What if Check Lists HAZOP FMEA FTA CPQRA Quantitative Quantitative FMEA, Failure Mode Effects Analysis is a preliminary qualitative technique that may require preliminary quantitative analysis (Mini-QRA) 23-10-2017В В· HAZOP severity levels. HAZOP identifies severity levels for event outcomes (typically four of five). Likelihood of occurrence. The HAZOP also identifies the frequency or likelihood of events ranging from 1 in 100 years to 1 in 100,000 years (i.e., not likely to ever occur).

The Actions may result in the change of the P&ID, operational instructions, drawings and design. A design cannot therefore be fit for purpose unless it has undergone a formally recorded and signed-off HAZOP. With our in-house designed HAZOP program, we can carry out formal HAZOP studies. HAZOP Team HAZOP is a team effort with a HAZOP Leader, a HAZOP Scribe who documents the analysis either manually (with an Excel sheet) or using a documentation software and Team members who contribute to the analysis 11.

HAZOP and FTA JosГ© Luis Fuentes-Bargues 1,* , MВЄ Carmen GonzГЎlez-Cruz 1, Cristina GonzГЎlez-Gaya 2 and MВЄ Piedad Baixauli-PГ©rez 3 1 Departamento de Proyectos de IngenierГa, Universitat PolitГЁcnica de ValГЁncia, Camino de Vera s/n, documentation of case study. 2. The Chemical Industry in Spain and Serious Accidents 2.1. We do not have books on HAZOP Analysis. But I have been able to find following websites on Internet which will be useful to you for information about it. 1. HAZOP Analysis Procedure. HAZOP Analysis Procedure. Hazards arise in a plant due to deviations from normal behavior; A …

HAZOP provides the opportunity for people to think creatively and examine ways in which hazards or operating problems might arise. To reduce the chance of missing something, a HAZOP is carried out in a systematic manner, using guide words to consider each pipeline and each type of hazard in turn. HAZOP COVERPAGE This form must be stapled to the required documentation* (relating to any SMOU and HAZOP performed). No one is to sign this form until the relevant documentation has been reviewed. The User is to keep this form and documentation in his/her Green Folder.

HAZOP Hazard Operability Study PharmaState Blog

HAZOP Procedure HAZOP Study HAZOP Analysis. The Actions may result in the change of the P&ID, operational instructions, drawings and design. A design cannot therefore be fit for purpose unless it has undergone a formally recorded and signed-off HAZOP. With our in-house designed HAZOP program, we can carry out formal HAZOP studies., This unit standard is for people who lead HAZOP studies in the workplace. Range documentation requirements include but are not limited to – worksheet, marked up master, final report content. 3.3 Nodes of an appropriate size are identified and marked up ….

Top ten tips for an effective HAZOP (part one) ESC

Why Proper PHA/HAZOP Documentation is Critical for LOPA. higher level compared to a HAZOP, What-If or bowtie study. HAZID can be conducted at a unit or system level with little documentation other than a design concept. HAZOP and What-if studies focus on a system or node level and are dependent on accurate process safety information., This unit standard is for people who lead HAZOP studies in the workplace. Range documentation requirements include but are not limited to – worksheet, marked up master, final report content. 3.3 Nodes of an appropriate size are identified and marked up ….

One individual must be assigned the task of recording the results. Applied in its fullest sense, a complete HAZOP study would require a large investment in time and effort by the people involved. Hazop Documentation Requirements. The following documents are essential at the start of a Hazop study, with the P&ID being the principal document: These variables can have an impact on the HAZOP/LOPA results; however, the value of HAZOP/LOPA sessions and quality/usability of resultant HAZOP/LOPA documentation is a critical objective and the primary responsibility for achieving this objective must fall on the shoulders of the facilitator. Key topics addressed within the paper include:

higher level compared to a HAZOP, What-If or bowtie study. HAZID can be conducted at a unit or system level with little documentation other than a design concept. HAZOP and What-if studies focus on a system or node level and are dependent on accurate process safety information. Sphera's process hazard analysis (PHA) & HAZOP software assists organizations with the implementation of risk studies with ease, accuracy, and efficiency.

Original HAZOP actions not completed Plant deterioration Changes in standards Increased awareness of pressure relief scenarios Adequacy of flare and blowdown systems Plant incidents Typical examples Poor or no HAZOP as part of management of change (MOC). Plant documentation not updated. Over/under pressurecase changes. Low temperature blow down HAZOP is a well recognized method of identifying hazards & problem which may prevent an efficient operation & lead to a hazard .HAZOP is a technique to critically examine a system, part by part ,in a very systematic manner ,to find out the cause and consequence of every conceivable deviations

HAZOP may be appropriate with more complex processes, such as batch reactors with multiple steps or at HP/LP interfaces on oil & gas facilities. ABB can offer a flexible approach where PHR is used for most of the review with an option to use HAZOP where required to provide additional вЂthoroughness’. Availability of operations based staff Those scheduling a HAZOP should take into account the review scope, the number of nodes to be reviewed, the provision of completed design drawings and documentation and the need to maintain team performance over an extended time-frame.

26-3-2014В В· Process safety information is covered, explaining how it is needed in order to conduct the review and management of change (MOC) is shown in the overall PHA work process to illustrate the relationship between PHA and MOC. With the foundation set, details of the HAZOP methodology, including report documentation are presented. Original HAZOP actions not completed Plant deterioration Changes in standards Increased awareness of pressure relief scenarios Adequacy of flare and blowdown systems Plant incidents Typical examples Poor or no HAZOP as part of management of change (MOC). Plant documentation not updated. Over/under pressurecase changes. Low temperature blow down

HAZOP and FTA JosГ© Luis Fuentes-Bargues 1,* , MВЄ Carmen GonzГЎlez-Cruz 1, Cristina GonzГЎlez-Gaya 2 and MВЄ Piedad Baixauli-PГ©rez 3 1 Departamento de Proyectos de IngenierГa, Universitat PolitГЁcnica de ValГЁncia, Camino de Vera s/n, documentation of case study. 2. The Chemical Industry in Spain and Serious Accidents 2.1. HAZOP/LOPA sessions and quality/usability of resultant HAZOP/LOPA documentation is a critical objective. The primary responsibility for achieving this objective must fall on the shoulders of the facilitator to provide streamlined support to navigate through the PHA process while accurately capturing

higher level compared to a HAZOP, What-If or bowtie study. HAZID can be conducted at a unit or system level with little documentation other than a design concept. HAZOP and What-if studies focus on a system or node level and are dependent on accurate process safety information. HAZOP and FTA JosГ© Luis Fuentes-Bargues 1,* , MВЄ Carmen GonzГЎlez-Cruz 1, Cristina GonzГЎlez-Gaya 2 and MВЄ Piedad Baixauli-PГ©rez 3 1 Departamento de Proyectos de IngenierГa, Universitat PolitГЁcnica de ValГЁncia, Camino de Vera s/n, documentation of case study. 2. The Chemical Industry in Spain and Serious Accidents 2.1.

View Demo Now. Tell me more? This is a Real E-learning program, with INTERACTIVE ANIMATIONS & SIMULATIONS that recreate plant situations, videos that explain concepts, real life examples and exercises, a full Case Study of a real process, concepts such as C-HAZOP , … Top ten tips for an effective HAZOP (part one) Posted on 15/03/2016. To make sure that all the correct documentation (see No. 2), personnel (see No. 3) and logistics (projector, refreshments etc.) are in place, at Engineering Safety Consultants (ESC), we issue a pre-HAZOP Checklist to …

The Actions may result in the change of the P&ID, operational instructions, drawings and design. A design cannot therefore be fit for purpose unless it has undergone a formally recorded and signed-off HAZOP. With our in-house designed HAZOP program, we can carry out formal HAZOP studies. HAZOP may be appropriate with more complex processes, such as batch reactors with multiple steps or at HP/LP interfaces on oil & gas facilities. ABB can offer a flexible approach where PHR is used for most of the review with an option to use HAZOP where required to provide additional вЂthoroughness’. Availability of operations based staff

HAZOP COVERPAGE This form must be stapled to the required documentation* (relating to any SMOU and HAZOP performed). No one is to sign this form until the relevant documentation has been reviewed. The User is to keep this form and documentation in his/her Green Folder. 24-1-2019 · We may think that It should be common sense to always have proper documentation in your Process Hazard Analysis (PHA) or Hazard and Operability (HAZOP) Study. Unfortunately, I have seen so many poorly documented PHAs that it really doesn't make sense to …

Moderation of the HAZOP meetings by an experienced, independent team leader. Recommendation of experts or specialists required for the HAZOP team. HAZOP study with the help of modern data processing and presentation techniques. Documentation of the HAZOP study results. These variables can have an impact on the HAZOP/LOPA results; however, the value of HAZOP/LOPA sessions and quality/usability of resultant HAZOP/LOPA documentation is a critical objective and the primary responsibility for achieving this objective must fall on the shoulders of the facilitator. Key topics addressed within the paper include:

How to Link HAZOP and LOPA to Calculate a Safety. Why Proper PHA/HAZOP Documentation is Critical for LOPA. Updated: Apr 7. This article can also be found on LinkedIn. See what people are saying. We may think that It should be common sense to always have proper documentation in your Process Hazard Analysis (PHA) …, A HAZOP software merely documents the HAZOP, which BTW a human is supposed to do, as part of a team of multidisciplinary experts.In that sense, it should be called a HAZOP documenting software and not as a HAZOP analysis software. The only advantage that I see is that the HAZOP software allows you to document everything in a structured way..

HAZARD IDENTIFICATION (HAZID) STUDIES TERMS OF REFERENCE

HAZOP procedure TЬV SЬD UK. Documentation of the HAZOP study results. We also provide support in the application of other systematic methods such as failure analysis, event sequence analysis, fault tree analysis and (semi-)quantitative risk analysis. Your Benefits., HAZOP Study Documentation. At each session, scenarios that are identified by the study team are recorded in worksheets, often using custom software, such as PHAWorks RA Edition. Worksheets serve several purposes including: Checking by the facilitator / leader and team members after each session;.

HAZOP procedure TЬV SЬD UK. HAZOP and FTA JosГ© Luis Fuentes-Bargues 1,* , MВЄ Carmen GonzГЎlez-Cruz 1, Cristina GonzГЎlez-Gaya 2 and MВЄ Piedad Baixauli-PГ©rez 3 1 Departamento de Proyectos de IngenierГa, Universitat PolitГЁcnica de ValГЁncia, Camino de Vera s/n, documentation of case study. 2. The Chemical Industry in Spain and Serious Accidents 2.1., HAZOP provides the opportunity for people to think creatively and examine ways in which hazards or operating problems might arise. To reduce the chance of missing something, a HAZOP is carried out in a systematic manner, using guide words to consider each pipeline and each type of hazard in turn..

Hazop analysis complete report SlideShare

HAZOP Series Module 11 HAZOP & LOPA Documentation Quality. Training Guide: Hazard & Operability Analysis (HAZOP) Page 7 of 9 2.4 Documentation & Follow-up Phase The documentation of HAZOP analyses is often facilitated by utilizing a template recording form as detailed in IEC Standard 61882. Risk assessment teams may modify the template as necessary based on factors such as: Regulatory requirements https://en.wikipedia.org/wiki/Hazop Procedure for Hazard and Operability Study (HAZOP) The purpose of this procedure is to describe application of Hazard and Operability Study (HAZOP) in risk managemnet process. The document is optimized for small and medium-sized organizations – we believe that overly complex and lengthy documents are just overkill for you..

We do not have books on HAZOP Analysis. But I have been able to find following websites on Internet which will be useful to you for information about it. 1. HAZOP Analysis Procedure. HAZOP Analysis Procedure. Hazards arise in a plant due to deviations from normal behavior; A … Sphera's process hazard analysis (PHA) & HAZOP software assists organizations with the implementation of risk studies with ease, accuracy, and efficiency.

26-3-2014В В· Process safety information is covered, explaining how it is needed in order to conduct the review and management of change (MOC) is shown in the overall PHA work process to illustrate the relationship between PHA and MOC. With the foundation set, details of the HAZOP methodology, including report documentation are presented. 18-12-2014В В· Risk Management Professionals brings you the eleventh module of an ongoing series which highlights our rigorous HAZOP study courses taught by seasoned professionals. Recorded at Risk Management Professionals' corporate headquarters in Irvine California on December 18, 2014. Presented by Steve Maher. For a .pdf copy of presentation

HAZOP Team HAZOP is a team effort with a HAZOP Leader, a HAZOP Scribe who documents the analysis either manually (with an Excel sheet) or using a documentation software and Team members who contribute to the analysis 11. Top ten tips for an effective HAZOP (part one) Posted on 15/03/2016. To make sure that all the correct documentation (see No. 2), personnel (see No. 3) and logistics (projector, refreshments etc.) are in place, at Engineering Safety Consultants (ESC), we issue a pre-HAZOP Checklist to …

Why Proper PHA/HAZOP Documentation is Critical for LOPA. Updated: Apr 7. This article can also be found on LinkedIn. See what people are saying. We may think that It should be common sense to always have proper documentation in your Process Hazard Analysis (PHA) … Another key step in the safety risk assessment process is safety assessment documentation and the use of Hazard Logs to document the output of hazards identification is also described and an example hazard log template provided. Some examples of hazards and information sources that could be used to identify hazards are also provided as annexes.

One individual must be assigned the task of recording the results. Applied in its fullest sense, a complete HAZOP study would require a large investment in time and effort by the people involved. Hazop Documentation Requirements. The following documents are essential at the start of a Hazop study, with the P&ID being the principal document: HAZOP and FTA JosГ© Luis Fuentes-Bargues 1,* , MВЄ Carmen GonzГЎlez-Cruz 1, Cristina GonzГЎlez-Gaya 2 and MВЄ Piedad Baixauli-PГ©rez 3 1 Departamento de Proyectos de IngenierГa, Universitat PolitГЁcnica de ValГЁncia, Camino de Vera s/n, documentation of case study. 2. The Chemical Industry in Spain and Serious Accidents 2.1.

HAZOP/LOPA sessions and quality/usability of resultant HAZOP/LOPA documentation is a critical objective. The primary responsibility for achieving this objective must fall on the shoulders of the facilitator to provide streamlined support to navigate through the PHA process while accurately capturing – Documentation of the HAZOP study results. – We also provide HAZOP training. Furthermore, we also provide support in the application of other systematic methods such as failure analysis, event sequence analysis and fault tree analysis. Your Benefits.

Procedure for Hazard and Operability Study (HAZOP) The purpose of this procedure is to describe application of Hazard and Operability Study (HAZOP) in risk managemnet process. The document is optimized for small and medium-sized organizations – we believe that overly complex and lengthy documents are just overkill for you. HAZOP Team HAZOP is a team effort with a HAZOP Leader, a HAZOP Scribe who documents the analysis either manually (with an Excel sheet) or using a documentation software and Team members who contribute to the analysis

HAZOP Study Documentation. At each session, scenarios that are identified by the study team are recorded in worksheets, often using custom software, such as PHAWorks RA Edition. Worksheets serve several purposes including: Checking by the facilitator / leader and team members after each session; higher level compared to a HAZOP, What-If or bowtie study. HAZID can be conducted at a unit or system level with little documentation other than a design concept. HAZOP and What-if studies focus on a system or node level and are dependent on accurate process safety information.

These variables can have an impact on the HAZOP/LOPA results; however, the value of HAZOP/LOPA sessions and quality/usability of resultant HAZOP/LOPA documentation is a critical objective and the primary responsibility for achieving this objective must fall on the shoulders of the facilitator. Key topics addressed within the paper include: Procedure for Hazard and Operability Study (HAZOP) The purpose of this procedure is to describe application of Hazard and Operability Study (HAZOP) in risk managemnet process. The document is optimized for small and medium-sized organizations – we believe that overly complex and lengthy documents are just overkill for you.

Procedure for Hazard and Operability Study (HAZOP) The purpose of this procedure is to describe application of Hazard and Operability Study (HAZOP) in risk managemnet process. The document is optimized for small and medium-sized organizations – we believe that overly complex and lengthy documents are just overkill for you. Hazard identification techniques such as HAZOP derive their power from a disciplined step by step examination process. 4. Documentation & Follow-up Phase. The documentation of HAZOP analyses is often facilitated by utilizing a template recording form as detailed in IEC Standard 61882.

HAZOP Team HAZOP is a team effort with a HAZOP Leader, a HAZOP Scribe who documents the analysis either manually (with an Excel sheet) or using a documentation software and Team members who contribute to the analysis 11. higher level compared to a HAZOP, What-If or bowtie study. HAZID can be conducted at a unit or system level with little documentation other than a design concept. HAZOP and What-if studies focus on a system or node level and are dependent on accurate process safety information.