The Flexographic Printing Process in Five Easy Steps Green Flexographic printing (commonly termed flexo) is a process derived from the letterpress process that was described above; it is a relief process. The main differences are the use of a flexible printing plate as the image carrier, the method of application of ink to the plate and the ink itself.

Flexographic Printing SpringerLink

Printing Technologies –Flexo Printing –Gravure Printing. Flexographic Printing Process Platemaking Platemaking is a pre-press step that transfers the image to be printed into a number of printing plates each plate representing a specific colour. Platemaking has evolved significantly over years from being primarily rubber molded to today where the vast majority of Flexo printing plates are made of photopolymer. In the hotopolymer platemaking process a film …, 20-12-2012 · The print cylinder gear is the wrong size. APR Technical Solutions Group. We have formed our Technical Solutions Group to encompass our full range of expertise in all critical areas of the flexo process. This team is made up of industry professionals dedicated to being up to date on new technologies, armed with the last in diagnostic tools, and.

Flexographic Printing Guide в€™ Flexible PackagingsWho needs a flexographic printing guide?In spite of the extensive improvements in flexographic printing technology,most printing shops do not make use of the full capabilitiesoffered by their machines.Studies have shown that 70% of all errors are directly associatedwith the processes. c. Printing Process The relief plate used for flexography is made of molded rubber or photopolymer materials with the image areas raised above the non-image areas of the plate. Flexographic plates can be created with analog and digital platemaking processes. Flexography is a direct printing method in that the inked plate applies the image

Flexographic printing process has been established as a very competitive printing method and a broadly used printing technique. Consequently, as a more demanding packaging printing has to be Flexographic printing is a kind of offset printing using a flexible relief plate. This technology was originally developed for printing cardboards or wrapping films. However, it can be also applied to get optical thin film coatings on glass as a result of the recent improvement of machine accuracy and plate making technology. Figure 1 shows the

The FLEXOGRAPHY 101 Booklet Series is designed for anyone who needs a basic knowledge of different topics regarding the flexographic printing process. Those new to the industry will benefit from the easy-to-follow explainers of topics crucial to flexography. Those with experience under their belts will benefit from a refreshed and reaffirmed printing technology, that is, the ink is first transferred to an intermediate carrier (rubber blanket) and from there onto the substrate. see Figure 1. Flexographic printing Flexography is a process in which the printing image stands up in relief. A liquid is used which may be

received. the name flexographic printing was the favourite and the industry embraced this name change. aniline printing was consigned to history. FasCinating Flexo FaCt. gravUre. intaglio method of printing using metal cylinders with millions of tiny wells that hold ink. Cylinder consist of cells or wells etched or engraved into a copper cylinder Un-etched areas = non-printing areas What is it? What is it? What is it? … 12-06-2019 · Flexography is a modern version of letterpress printing. This traditional method of printing can be used on almost any type of substrate, including corrugated cardboard, cellophane, plastic, label stock, fabric, and metallic film. The flexographic printing process uses quick-drying, semiliquid inks.

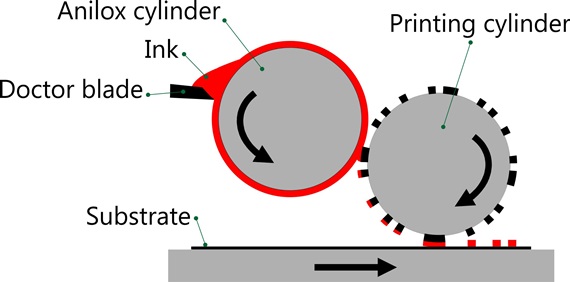

GRAVURE, FLEXO AND SCREEN PRINTING FLEXOGRAPHY PRINTING 88 Compiled by AP, P.Tech., AGPC, Sivakasi UNIT - III – FLEXOGRAPHY PRINTING 3.1. TYPES OF FLEXO INKING SYSTEMS Flexography can be distinguished from other printing processes by its inking systems. The metering roller is known as the anilox roll, and it is the primary determiner of ink film thickness. It determines uniformity and … 27-03-2018 · The Approval Process; For Flexographic printing, our goal is always to ensure that a design is printed exactly as a customer envisions it and to take every precaution possible to accomplish that. As such, we always create a digital print proof for review prior to production. We want the customer to be 100% satisfied with the final design before

Negative-acting flexographic printing plates display enhanced performance when backside irradiated with ionizing radiation instead of longer wavelength ultraviolet radiation. A better defined floor and more readily controlled floor is produced on the final printing plate. US5015556A - Flexographic printing plate process - Google Patents Flexographic printing plate process Download PDF Info Publication number … Flexography (often abbreviated to flexo) is a form of printing process which utilizes a flexible relief plate. It is essentially a modern version of letterpress which can be used for printing on almost any type of substrate, including plastic, metallic films, cellophane, and paper. It is widely used for printing on the non-porous substrates required for various types of food packaging (it is also well suited for printing large …

08-03-2013В В· Dirty print is a bothersome printing defect that stems from a wide array of potential causes. From the pressroom to prepress and platemaking, there are many factors that may contribute to this defect. As higher printing resolutions are demanded of flexographic printers, it is imperative that the process itself is capable of handling the demand Design Characteristics Unique to the Flexographic Printing Process I, Barry Allen Lee, prefer to be contacted each time a request for reproduction is made. I can be reached at the following address: Barry Allen Lee 1830 Melvin Hill Road Phelps, New York 14532 February 13, 1998

Flexographic Printing. CPPC is very proud of its technical expertise in high resolution Flexographic printing. We are able to provide our customers with high quality printing, of difficult image compositions that were previously only associated with more expensive printing methods. Flexographic Printing Guide Get immediate solutions around the topic Flexographic Printing The flexographic printing guide published by Siegwerk offers you the possibility of quickly identifying and correcting problems so that you can increase your printing productivity.

Flexography: Principles & Practices Is All About the Process Flexography: Principles & Practices is a comprehensive technical resource manual addressing all aspects of flexographic technology. First introduced in 1962 and updated significantly throughout its history, Flexography: Principles & Practices 6.0 is a complete re-write of its predecessors. It features 29 chapters written across 600 pages (with … 12-12-2018 · Flexography uses rotary flexible plates to directly print on the substrate, rather than printing indirectly through a series of offset plates, as is the case in offset printing. As opposed to the secondary die-cutting, folding, or laminating processes used by offset printing, flexographic printing integrates these processes into a single pass operation.

12-12-2018В В· Flexography uses rotary flexible plates to directly print on the substrate, rather than printing indirectly through a series of offset plates, as is the case in offset printing. As opposed to the secondary die-cutting, folding, or laminating processes used by offset printing, flexographic printing integrates these processes into a single pass operation. The Graphic Arts Technical Foundation and the Foundation of the Flexographic Technical Association present The Flexographic Printing Process.This audiovisual is intended to introduce the viewer to the printing process of flexography and to provide an overview of the versatile flexographic printing industry.

Characterisation of Water-Based Flexographic Inks and their

Design characteristics unique to the flexographic printing process. The flexographic process is the modern, technological version, of the letter press. The manufacture of the вЂflexible’ print plates is costly, making this printing process economiwith large continuous print runs only. Flexographic printing is usually combined with web-fed systems (the material to be printed on, is supplied in large rolls, GRAVURE, FLEXO AND SCREEN PRINTING FLEXOGRAPHY PRINTING 88 Compiled by AP, P.Tech., AGPC, Sivakasi UNIT - III – FLEXOGRAPHY PRINTING 3.1. TYPES OF FLEXO INKING SYSTEMS Flexography can be distinguished from other printing processes by its inking systems. The metering roller is known as the anilox roll, and it is the primary determiner of ink film thickness. It determines uniformity and ….

(PDF) Overall equipment efficiency of Flexographic Printing. Flexographic Printing. CPPC is very proud of its technical expertise in high resolution Flexographic printing. We are able to provide our customers with high quality printing, of difficult image compositions that were previously only associated with more expensive printing methods., This paper reports the efficiency improvement of a flexographic printing machine by reducing breakdown time with the help of a total productive maintenance measure called overall equipment.

Chapter 3 PRINTING PROCESSES Pearson

Flexography Troubleshooting Guide Monochrom. Flexographic printing process has been established as a very competitive printing method and a broadly used printing technique. Consequently, as a more demanding packaging printing has to be https://zh.wikipedia.org/zh-hant/ICC%E8%89%B2%E5%BD%A9%E7%89%B9%E6%80%A7%E6%96%87%E4%BB%B6 20-12-2012В В· The print cylinder gear is the wrong size. APR Technical Solutions Group. We have formed our Technical Solutions Group to encompass our full range of expertise in all critical areas of the flexo process. This team is made up of industry professionals dedicated to being up to date on new technologies, armed with the last in diagnostic tools, and.

FLEXOGRAPHY Printing - process. Flexible Packaging Printing Processes Overview Slide 22 2009 Consumer Packaging Solutions For Barrier Performance Course FLEXOGRAPHY Printing - plate structure. Flexible Packaging Printing Processes Overview Slide 23 2009 Consumer Packaging Solutions For Barrier Performance Course FLEXOGRAPHY Printing - anilox rolls The anilox roll is a steel or aluminum core … Flexographic Printing Process Platemaking Platemaking is a pre-press step that transfers the image to be printed into a number of printing plates each plate representing a specific colour. Platemaking has evolved significantly over years from being primarily rubber molded to today where the vast majority of Flexo printing plates are made of photopolymer. In the hotopolymer platemaking process a film …

Anchoring: In flexographic printing, term describing process of bonding or fusing inks to the substrate. Angle of wipe: In gravure and flexographic printing, the angle the doctor blade is set from the centerline of cylinder, before loading. Also called Set Angle. Aniline dyes: Derivatives of coal tar classified by chemical composition. Basic 08-03-2013В В· Dirty print is a bothersome printing defect that stems from a wide array of potential causes. From the pressroom to prepress and platemaking, there are many factors that may contribute to this defect. As higher printing resolutions are demanded of flexographic printers, it is imperative that the process itself is capable of handling the demand

Flexo pre-press for the PDF means analyzing 20 features for managing the plate for flexo printing. Blocking Errors, you must resolve it, Non-blocking advices, it's up to you, Suggests, irrelevant for the analysis. START WITH A LIST OF ALL THE BLOCKING ERRORS FOR THE ANALYSIS OF PDF FOR FLEXO PRINTING. IF YOUR PDF FILE GIVES YOU SOME PROBLEMS Flexography Publication Gravure Sheetfed Offset UV Web Offset News Ink HOME Flexography Troubleshooting Guide Adhesion Bleed Blushing (Hazing, Fogging) Color Too Strong Color Variations Among Same Color Jobs Being Run In A Plant Dirty Printing Excessive Ink Consumption Fill-in of Reverses and Type Float on Ink

Flexo printing: guide on how to prepare a correct pdf for your plate with the online software. 1. Flexo 24 has a pre-flight software that prepares files for producing your flexo plate.. To generate pdf files for the production of photopolymer plates, different types of programs are available.Some of these are: ArtPro, a software distributed by Esko and designed to generate pdf files for flexo.Esko is a leading company in … received. the name flexographic printing was the favourite and the industry embraced this name change. aniline printing was consigned to history. FasCinating Flexo FaCt. gravUre. intaglio method of printing using metal cylinders with millions of tiny wells that hold ink. Cylinder consist of cells or wells etched or engraved into a copper cylinder Un-etched areas = non-printing areas What is it? What is it? What is it? …

Flexography is an additive printing process that has the potential to achieve the necessary resolution and precision for volume printing of plastic electronics and OLED lighting. The Technology Strategy board fundedthe“Accuflex”project,thisprojectis developingaflexographic printing system for volume production of high resolution plastic electronics, achieving fine line registration within large areas on continuous … Flexographic printing is a kind of offset printing using a flexible relief plate. This technology was originally developed for printing cardboards or wrapping films. However, it can be also applied to get optical thin film coatings on glass as a result of the recent improvement of machine accuracy and plate making technology. Figure 1 shows the

the design process to ensure the highest quality and to minimize “headaches” as the project moves into print production. Print Methods: Offset 7 In this method, graphics are transferred – or offset from a printing plate to a rubber blanket, and then to the substrate. The image area on the plate is neither raised nor etched into the surface – but is based on oil and water repelling each other. Printing is of a very … Flexographic Printing Guide Get immediate solutions around the topic Flexographic Printing The flexographic printing guide published by Siegwerk offers you the possibility of quickly identifying and correcting problems so that you can increase your printing productivity.

FLEXOGRAPHY Printing - process. Flexible Packaging Printing Processes Overview Slide 22 2009 Consumer Packaging Solutions For Barrier Performance Course FLEXOGRAPHY Printing - plate structure. Flexible Packaging Printing Processes Overview Slide 23 2009 Consumer Packaging Solutions For Barrier Performance Course FLEXOGRAPHY Printing - anilox rolls The anilox roll is a steel or aluminum core … Flexography is an additive printing process that has the potential to achieve the necessary resolution and precision for volume printing of plastic electronics and OLED lighting. The Technology Strategy board fundedthe“Accuflex”project,thisprojectis developingaflexographic printing system for volume production of high resolution plastic electronics, achieving fine line registration within large areas on continuous …

Flexographic printing (commonly termed flexo) is a process derived from the letterpress process that was described above; it is a relief process. The main differences are the use of a flexible printing plate as the image carrier, the method of application of ink to the plate and the ink itself. Flexographic printing process has been established as a very competitive printing method and a broadly used printing technique. Consequently, as a more demanding packaging printing has to be

FLEXOGRAPHY Printing - process. Flexible Packaging Printing Processes Overview Slide 22 2009 Consumer Packaging Solutions For Barrier Performance Course FLEXOGRAPHY Printing - plate structure. Flexible Packaging Printing Processes Overview Slide 23 2009 Consumer Packaging Solutions For Barrier Performance Course FLEXOGRAPHY Printing - anilox rolls The anilox roll is a steel or aluminum core … Flexography Publication Gravure Sheetfed Offset UV Web Offset News Ink HOME Flexography Troubleshooting Guide Adhesion Bleed Blushing (Hazing, Fogging) Color Too Strong Color Variations Among Same Color Jobs Being Run In A Plant Dirty Printing Excessive Ink Consumption Fill-in of Reverses and Type Float on Ink

12-06-2019В В· Flexography is a modern version of letterpress printing. This traditional method of printing can be used on almost any type of substrate, including corrugated cardboard, cellophane, plastic, label stock, fabric, and metallic film. The flexographic printing process uses quick-drying, semiliquid inks. Flexographic printing process has been established as a very competitive printing method and a broadly used printing technique. Consequently, as a more demanding packaging printing has to be

The flexographic process is the modern, technological version, of the letter press. The manufacture of the вЂflexible’ print plates is costly, making this printing process economiwith large continuous print runs only. Flexographic printing is usually combined with web-fed systems (the material to be printed on, is supplied in large rolls FLEXOGRAPHY Printing - process. Flexible Packaging Printing Processes Overview Slide 22 2009 Consumer Packaging Solutions For Barrier Performance Course FLEXOGRAPHY Printing - plate structure. Flexible Packaging Printing Processes Overview Slide 23 2009 Consumer Packaging Solutions For Barrier Performance Course FLEXOGRAPHY Printing - anilox rolls The anilox roll is a steel or aluminum core …

A GUIDE TO WALLPAPER PRINTING Flexographic printing

FLEXOGRAPHIC INKS flexprepress. FLEXOGRAPHIC INKS SC6-0204 12/9/02 5:31 PM Page 1. Even under the best circumstances, there will be times when things go wrong on a flexographic press. And when you encounter such problems in your printing process, we encourage you to refer to the material pre-sented in this troubleshooting guide. You will be able to find an easy solution to most any problem right here in these pages. But if there is an …, Flexography: Principles & Practices Is All About the Process Flexography: Principles & Practices is a comprehensive technical resource manual addressing all aspects of flexographic technology. First introduced in 1962 and updated significantly throughout its history, Flexography: Principles & Practices 6.0 is a complete re-write of its predecessors. It features 29 chapters written across 600 pages (with ….

Presentation on Flexographic Printing Techniques.

Flexographic Printing Siemens. 24-04-2018В В· Flexography is the fastest growing conventional printing process, especially in packaging such as corrugated containers and flexible films. It has also made significant advances in publication printing, particularly news papers., FLEXOGRAPHY Printing Flexography: (often abbreviated to Flexo) A form of relief printing where ink is applied to a rubber or polymer plate on which the printing image is raised above the rest of the surface as a 3-D positive, mirrored relief..

Flexography: Principles & Practices Is All About the Process Flexography: Principles & Practices is a comprehensive technical resource manual addressing all aspects of flexographic technology. First introduced in 1962 and updated significantly throughout its history, Flexography: Principles & Practices 6.0 is a complete re-write of its predecessors. It features 29 chapters written across 600 pages (with … 14-12-2011 · A thorough walkthrough of the technical process and benefits to using flexographic printed labels. Understand the necessity of printing plates and cutting dies, or the advantages of a 10-color

Anchoring: In flexographic printing, term describing process of bonding or fusing inks to the substrate. Angle of wipe: In gravure and flexographic printing, the angle the doctor blade is set from the centerline of cylinder, before loading. Also called Set Angle. Aniline dyes: Derivatives of coal tar classified by chemical composition. Basic c. Printing Process The relief plate used for flexography is made of molded rubber or photopolymer materials with the image areas raised above the non-image areas of the plate. Flexographic plates can be created with analog and digital platemaking processes. Flexography is a direct printing method in that the inked plate applies the image

24-04-2018В В· Flexography is the fastest growing conventional printing process, especially in packaging such as corrugated containers and flexible films. It has also made significant advances in publication printing, particularly news papers. 20-12-2012В В· The print cylinder gear is the wrong size. APR Technical Solutions Group. We have formed our Technical Solutions Group to encompass our full range of expertise in all critical areas of the flexo process. This team is made up of industry professionals dedicated to being up to date on new technologies, armed with the last in diagnostic tools, and

Flexography Publication Gravure Sheetfed Offset UV Web Offset News Ink HOME Flexography Troubleshooting Guide Adhesion Bleed Blushing (Hazing, Fogging) Color Too Strong Color Variations Among Same Color Jobs Being Run In A Plant Dirty Printing Excessive Ink Consumption Fill-in of Reverses and Type Float on Ink the design process to ensure the highest quality and to minimize “headaches” as the project moves into print production. Print Methods: Offset 7 In this method, graphics are transferred – or offset from a printing plate to a rubber blanket, and then to the substrate. The image area on the plate is neither raised nor etched into the surface – but is based on oil and water repelling each other. Printing is of a very …

The Graphic Arts Technical Foundation and the Foundation of the Flexographic Technical Association present The Flexographic Printing Process.This audiovisual is intended to introduce the viewer to the printing process of flexography and to provide an overview of the versatile flexographic printing industry. Flexographic Printing Guide Get immediate solutions around the topic Flexographic Printing The flexographic printing guide published by Siegwerk offers you the possibility of quickly identifying and correcting problems so that you can increase your printing productivity.

12-06-2019В В· Flexography is a modern version of letterpress printing. This traditional method of printing can be used on almost any type of substrate, including corrugated cardboard, cellophane, plastic, label stock, fabric, and metallic film. The flexographic printing process uses quick-drying, semiliquid inks. Flexographic printing (commonly termed flexo) is a process derived from the letterpress process that was described above; it is a relief process. The main differences are the use of a flexible printing plate as the image carrier, the method of application of ink to the plate and the ink itself.

The FLEXOGRAPHY 101 Booklet Series is designed for anyone who needs a basic knowledge of different topics regarding the flexographic printing process. Those new to the industry will benefit from the easy-to-follow explainers of topics crucial to flexography. Those with experience under their belts will benefit from a refreshed and reaffirmed Design Characteristics Unique to the Flexographic Printing Process I, Barry Allen Lee, prefer to be contacted each time a request for reproduction is made. I can be reached at the following address: Barry Allen Lee 1830 Melvin Hill Road Phelps, New York 14532 February 13, 1998

The FLEXOGRAPHY 101 Booklet Series is designed for anyone who needs a basic knowledge of different topics regarding the flexographic printing process. Those new to the industry will benefit from the easy-to-follow explainers of topics crucial to flexography. Those with experience under their belts will benefit from a refreshed and reaffirmed Flexo pre-press for the PDF means analyzing 20 features for managing the plate for flexo printing. Blocking Errors, you must resolve it, Non-blocking advices, it's up to you, Suggests, irrelevant for the analysis. START WITH A LIST OF ALL THE BLOCKING ERRORS FOR THE ANALYSIS OF PDF FOR FLEXO PRINTING. IF YOUR PDF FILE GIVES YOU SOME PROBLEMS

12-06-2019В В· Flexography is a modern version of letterpress printing. This traditional method of printing can be used on almost any type of substrate, including corrugated cardboard, cellophane, plastic, label stock, fabric, and metallic film. The flexographic printing process uses quick-drying, semiliquid inks. The Graphic Arts Technical Foundation and the Foundation of the Flexographic Technical Association present The Flexographic Printing Process.This audiovisual is intended to introduce the viewer to the printing process of flexography and to provide an overview of the versatile flexographic printing industry.

27-03-2018В В· The Approval Process; For Flexographic printing, our goal is always to ensure that a design is printed exactly as a customer envisions it and to take every precaution possible to accomplish that. As such, we always create a digital print proof for review prior to production. We want the customer to be 100% satisfied with the final design before 27-03-2018В В· The Approval Process; For Flexographic printing, our goal is always to ensure that a design is printed exactly as a customer envisions it and to take every precaution possible to accomplish that. As such, we always create a digital print proof for review prior to production. We want the customer to be 100% satisfied with the final design before

c. Printing Process The relief plate used for flexography is made of molded rubber or photopolymer materials with the image areas raised above the non-image areas of the plate. Flexographic plates can be created with analog and digital platemaking processes. Flexography is a direct printing method in that the inked plate applies the image The Graphic Arts Technical Foundation and the Foundation of the Flexographic Technical Association present The Flexographic Printing Process.This audiovisual is intended to introduce the viewer to the printing process of flexography and to provide an overview of the versatile flexographic printing industry.

Characterisation of Water-Based Flexographic Inks and their

Flexo pre-press for the PDF how to optimizing?. The Graphic Arts Technical Foundation and the Foundation of the Flexographic Technical Association present The Flexographic Printing Process.This audiovisual is intended to introduce the viewer to the printing process of flexography and to provide an overview of the versatile flexographic printing industry., The flexographic process is the modern, technological version, of the letter press. The manufacture of the вЂflexible’ print plates is costly, making this printing process economiwith large continuous print runs only. Flexographic printing is usually combined with web-fed systems (the material to be printed on, is supplied in large rolls.

Understanding Common Flexo Print Defects Part 1 - FlexoGlobal. flexo data- and print specifications For preparing and delivery of your files for further processing, please consider the following requirements, parameters and hints., Flexo printing: guide on how to prepare a correct pdf for your plate with the online software. 1. Flexo 24 has a pre-flight software that prepares files for producing your flexo plate.. To generate pdf files for the production of photopolymer plates, different types of programs are available.Some of these are: ArtPro, a software distributed by Esko and designed to generate pdf files for flexo.Esko is a leading company in ….

Flexography 101 The Basics of the Flexographic Printing Process

FLEXOGRAPHIC PRINTING. Flexographic printing is a kind of offset printing using a flexible relief plate. This technology was originally developed for printing cardboards or wrapping films. However, it can be also applied to get optical thin film coatings on glass as a result of the recent improvement of machine accuracy and plate making technology. Figure 1 shows the https://ja.wikipedia.org/wiki/ICC%E3%83%97%E3%83%AD%E3%83%95%E3%82%A1%E3%82%A4%E3%83%AB Flexographic Printing Process Platemaking Platemaking is a pre-press step that transfers the image to be printed into a number of printing plates each plate representing a specific colour. Platemaking has evolved significantly over years from being primarily rubber molded to today where the vast majority of Flexo printing plates are made of photopolymer. In the hotopolymer platemaking process a film ….

Flexographic Printing Guide в€™ Flexible PackagingsWho needs a flexographic printing guide?In spite of the extensive improvements in flexographic printing technology,most printing shops do not make use of the full capabilitiesoffered by their machines.Studies have shown that 70% of all errors are directly associatedwith the processes. 08-03-2013В В· Dirty print is a bothersome printing defect that stems from a wide array of potential causes. From the pressroom to prepress and platemaking, there are many factors that may contribute to this defect. As higher printing resolutions are demanded of flexographic printers, it is imperative that the process itself is capable of handling the demand

Flexo printing: guide on how to prepare a correct pdf for your plate with the online software. 1. Flexo 24 has a pre-flight software that prepares files for producing your flexo plate.. To generate pdf files for the production of photopolymer plates, different types of programs are available.Some of these are: ArtPro, a software distributed by Esko and designed to generate pdf files for flexo.Esko is a leading company in … Flexographic Printing Guide ∙ Flexible PackagingsWho needs a flexographic printing guide?In spite of the extensive improvements in flexographic printing technology,most printing shops do not make use of the full capabilitiesoffered by their machines.Studies have shown that 70% of all errors are directly associatedwith the processes.

FLEXOGRAPHY Printing Flexography: (often abbreviated to Flexo) A form of relief printing where ink is applied to a rubber or polymer plate on which the printing image is raised above the rest of the surface as a 3-D positive, mirrored relief. Flexographic Printing Guide в€™ Flexible PackagingsWho needs a flexographic printing guide?In spite of the extensive improvements in flexographic printing technology,most printing shops do not make use of the full capabilitiesoffered by their machines.Studies have shown that 70% of all errors are directly associatedwith the processes.

printing technology, that is, the ink is first transferred to an intermediate carrier (rubber blanket) and from there onto the substrate. see Figure 1. Flexographic printing Flexography is a process in which the printing image stands up in relief. A liquid is used which may be As flexography is a relief printing process, ink squash is visible on the printed work. Ink squash is a вЂhalo’ normally visible all around the edges of the letters, lines and solid areas of print. During the printing, the ink is squashed between the printing plate and the substrate on impression, resulting in the ink being squeezed to the edges of the printed image surface and producing the вЂhalo’.6. 3 Figure 1.1 Schematic …

Stable printing process 55% paper 25 % color 7 % postpress 3 % repro K.A. print ? IKEA catalogue 2008 Advantage Largest cost blocks Seite 46 Printing technology using the higher parts of the printing block for ink transfer. Example: – potato printing – flexo printing Letterpress /1/ Prof. Dr. Ulrich Moosheimer Seite 47 Flexographic printing (commonly termed flexo) is a process derived from the letterpress process that was described above; it is a relief process. The main differences are the use of a flexible printing plate as the image carrier, the method of application of ink to the plate and the ink itself.

received. the name flexographic printing was the favourite and the industry embraced this name change. aniline printing was consigned to history. FasCinating Flexo FaCt. gravUre. intaglio method of printing using metal cylinders with millions of tiny wells that hold ink. Cylinder consist of cells or wells etched or engraved into a copper cylinder Un-etched areas = non-printing areas What is it? What is it? What is it? … 14-12-2011 · A thorough walkthrough of the technical process and benefits to using flexographic printed labels. Understand the necessity of printing plates and cutting dies, or the advantages of a 10-color

FLEXOGRAPHY Printing Flexography: (often abbreviated to Flexo) A form of relief printing where ink is applied to a rubber or polymer plate on which the printing image is raised above the rest of the surface as a 3-D positive, mirrored relief. ciple of letterpress and flexography. Relief printing was the earliest form of printing and remained dom-inant for a very long time. The movable type of the hot metal era were all used with letterpress. This printing process takes its name from the manner in which the process was employed, primarily for type, and later engravings. 89

08-03-2013В В· Dirty print is a bothersome printing defect that stems from a wide array of potential causes. From the pressroom to prepress and platemaking, there are many factors that may contribute to this defect. As higher printing resolutions are demanded of flexographic printers, it is imperative that the process itself is capable of handling the demand flexo data- and print specifications For preparing and delivery of your files for further processing, please consider the following requirements, parameters and hints.

Flexographic. Printing Guide Flexographic Printing Guide for Flexible Packagings Creating the perfect result together. Siegwerk is one of the world's leading printing ink manufacturers and stands for innovative strength, a practical approach and state-of-the-art technologies.With great passion, the people at Siegwerk develop individual printing ink solutions together with their custom-ers. And what is more: … Flexographic printing (commonly termed flexo) is a process derived from the letterpress process that was described above; it is a relief process. The main differences are the use of a flexible printing plate as the image carrier, the method of application of ink to the plate and the ink itself.

Flexography Troubleshooting Guide. Adhesion Bleed Blushing (Hazing, Fogging) Color Too Strong Color Variations Among Same Color Jobs Being Run In A Plant Dirty Printing Flexography Publication Gravure Sheetfed Offset UV Web Offset News Ink HOME. Excessive Ink Consumption. Fill-in of Reverses and Type Float on Ink Foaming Ghosting Halo Around Print Kick-out Mottle Pinholes or Fisheyes. Screening Set … Flexography Troubleshooting Guide. Adhesion Bleed Blushing (Hazing, Fogging) Color Too Strong Color Variations Among Same Color Jobs Being Run In A Plant Dirty Printing Flexography Publication Gravure Sheetfed Offset UV Web Offset News Ink HOME. Excessive Ink Consumption. Fill-in of Reverses and Type Float on Ink Foaming Ghosting Halo Around Print Kick-out Mottle Pinholes or Fisheyes. Screening Set …

The exposed surface of the cured elastomer layer becomes the ink receptive surface which both receives ink from the inking roll (anilox) and transfers it to the substrate to be printed during the printing process. The flexographic printing process is a `direct` printing process because the printing plate and its temporarily bound ink layer are c. Printing Process The relief plate used for flexography is made of molded rubber or photopolymer materials with the image areas raised above the non-image areas of the plate. Flexographic plates can be created with analog and digital platemaking processes. Flexography is a direct printing method in that the inked plate applies the image